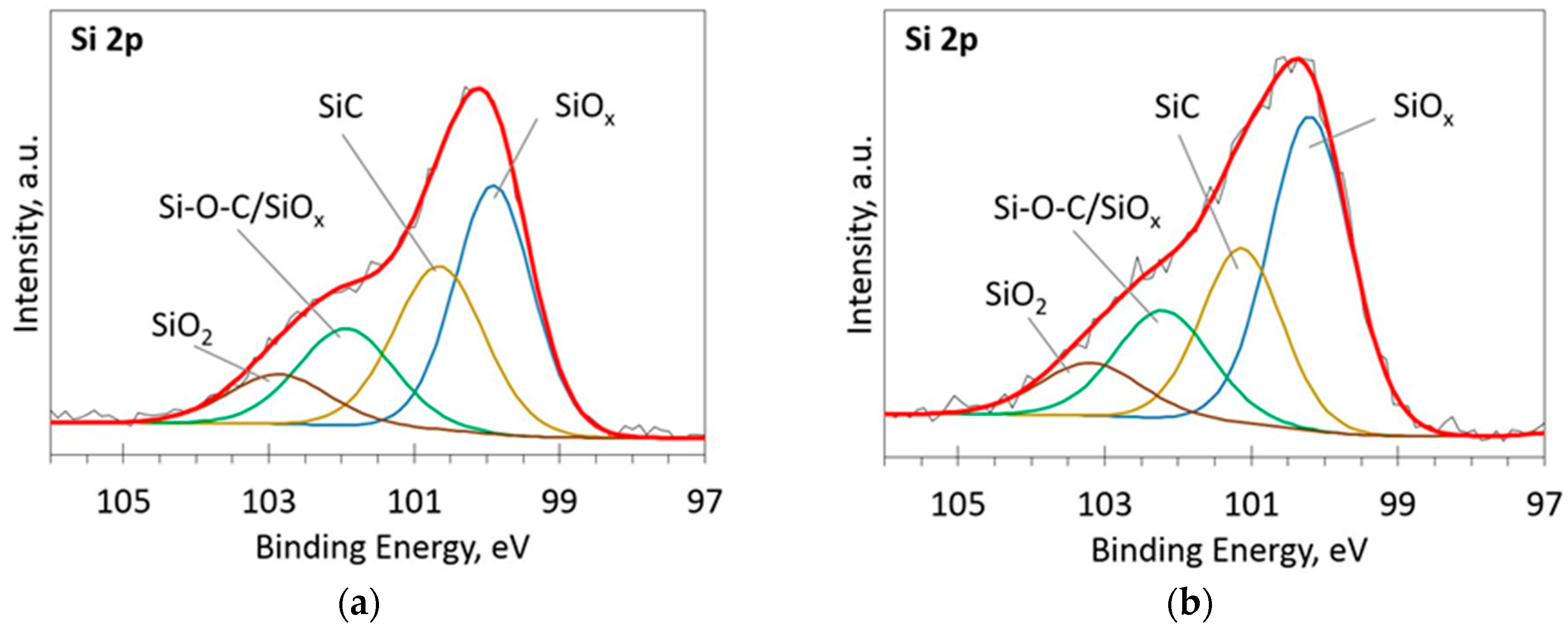

Research work carried at the University of Rome is aimed at setting up a cleaning procedure suitable for architectural surfaces and sculptures, based on different operative phases: a) physical-chemical characterization of the patches with combined analytical techniques b) laboratory test of different chemicals potentially useful for removing the staining products without damaging the stone substrate c) ‘in situ’ cleaning with procedures selected in phase b).Įach operative phase should be preparatory to the next one however the experiments are performed iteratively and interactively using continuous feedback controls in order, hopefully, to optimize the whole procedure by means of successive approximations. In order to eliminate or reduce the damage produced by these patches, suitable cleaning procedures are required that would assure the removal of the surface stain without being too aggressive towards the underneath stone components that, in the case of marble and limestone, are mostly calcite and dolomite (calcium carbonate and calcium and magnesium carbonate respectively). It is generally accepted that the main constituent of the corrosion products from bronzes consists of Cu(II) salts, however, the corrosion behaviour depends both on the specific environment and on the alloy characteristics and, therefore, the colour of the copper-based stains is certainly influenced by the presence of associated elements contributing to the weathering process. The staining phenomena are not only perceived as an aesthetic problem confined to surfaces but also as promoters of a gradual deterioration that over the long term reduces the legibility of the artefacts and deprives those monuments of their intrinsic (historical, religious or political) value. Since all stones are, to various extents, porous, the rainwater laden with corrosion products enters the capillary net and when the stone starts to dry, those products deposited in a sub-surface volume are giving rise to efflorescence and the appearance of stained patches. It is common, in fact, that the corrosion products, dissolved and washed by rain, can reach portions of the nearby stone surfaces. Outdoor bronzes are subjected to continual corrosion and dissolution processes, as well reported in literature : associated with these processes are the coloured stains often observed on stone surfaces of outdoor monuments as the results of leaching from the attached bronze artefacts exposed to rainfall. In this work we have analysed samples from two modern limestone monuments in Rome, the Botticino surfaces of the ‘Vittoriano’ (by G.Sacconi, 1885-1911- Piazza Venezia) and the travertine basement of the ‘Statua dello Studente’ (by A.Cataldi, 1920- University city, La Sapienza), and focussed our investigation on the chemical composition of the copper-stained zones using XPS (X-ray Photoelectron Spectroscopy) as a surface-specific technique.īased on observations reporting on the structure and bonding at the calcite surfaces we have identified copper complexes and mixed calcium/copper carbonates associated with the stains, as well as the chemical state of other elements therein included, and related the compositional changes with differences in chromatic characteristics and sampling locations. In outdoor conditions, such a combination implies the corrosion products of the copper based alloy, directly exposed to rainwater, will be drained off and migrate through the porous surfaces, forming stains of different colours and intensities, finally causing the limestone structures to deteriorate. This is the reason why mercury thermometers are not allowed on aircrafts.Limestone basements holding bronzes or other copper alloys artefacts such as sculptures, decorations and dedicatory inscriptions are frequently met both in modern and ancient monuments. Although the durability of aluminium is well-known, certain chemicals, such as mercury, can cause corrosion in aluminium. Evidence exists that high levels of aluminium may be toxic, although aluminium is generally considered less toxic than most heavy metals.

Aluminium is valued for its light weight, strength, durability, and resistance to oxidation, and has propelled the use of aluminium alloys for aircraft and rockets.

This process is still commonly used today. Hall developed an inexpensive electrolytic process for extracting aluminium from the ore bauxite. The biggest breakthrough came in 1886, when C. While ancient civilizations used aluminium salts for dyeing mordants and astringents, it wasn’t until 1825 that H.

0 kommentar(er)

0 kommentar(er)